Maxinol PM200 Polymers Polymaleic Acid

Aquapharm is an independent, family owned business manufacturing

high performance polymers, phosphonates, biocides

and biodegradable chelants which are delivered worldwide for home laundry &

industrial cleaning, membrane & thermal desalination, and industrial water treatment applications.

With investment into state-of-the-art research & development facilities,

processes & people, our mission is to equip your business with the most

cost-effective solutions.

By focussing on the demands of recirculating evaporative

cooling water processes, we have developed a new improved polymaleic acid

(PMA), Maxinol® PM200. PMA’s are long established components of

cooling water formulations, but their variable quality can often lead to

product instability & formulation problems. Such problems are avoided using

Aquapharm’s Maxinol® PM200.

MAXINOL PM200 PHYSICAL PROPERTIES

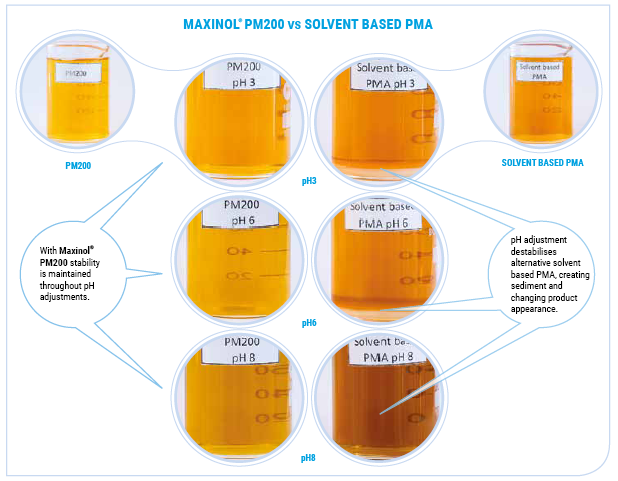

PRODUCT STABILITY

Process development at

Aquapharm has enabled an industrial scale solvent polymerisation of maleic

anhydride with unrivalled efficiency. Aquapharm delivers PMA with minimal

impurities and by-products, enhancing formulation stability and helping to

build confidence in your brand.

This can be observed by simple adjustment of product pH. Using

an alternative solvent based PMA, impurities readily precipitate, creating

sediment and changing product appearance. Maxinol® PM200 stability is maintained

throughout these adjustments. With Maxinol® PM200 you choose higher quality and

are less likely to experience formulation stability problems commonly

associated with other solvent based PMA’s.

HALOGEN

TOLERANCE

Maxinol® PM200 is at least as halogen tolerant

as other based PMA’s and will provide maximum flexibility for controlling

microbial activity in a cooling system.

MAXINOL®

PM200 CALCIUM CARBONATE & CALCIUM SULFATE INHIBITION PROPERTIES

Simple jar testing is frequently used to assess additives for

deposit control properties. Figures 1 & 2 reveal the superior performance

properties of Maxinol® PM200 versus an alternative solvent

based PMA.

MAXINOL®

PM200

CALCIUM

CARBONATE DYNAMIC TUBE BLOCK TEST

Dynamic tube block testing is another technique used to assess

the properties of additives, in this case their efficiency in supressing

crystal growth at surfaces. Figure 3 summarises data from experiments which

measure how pressure builds in stainless steel capillary tubes when solutions

of anions & cations are mixed together, in the absence & presence of

inhibitors. Clearly, Maxinol® PM200 is able

to moderate calcium carbonate growth long after alternative solvent PMA has

been overwhelmed. Polymers are tested at 1 mg/L as solids.

MAXINOL

PM200 SUMMARY

FEATURES/BENEFITS:

·

improved polymerisation efficiency delivers

a new high-purity maleic homopolymer

·

all-organic formulations are robust &

resilient eliminating stability & quality problems

·

efficiently stabilises recirculating

cooling water at high cycles of

concentration, offering both carbonate & sulfate deposit control

concentration, offering both carbonate & sulfate deposit control

·

minimises fresh water make-up, chemical

treatment & blowdown costs

·

effective over a wide range of water

chemistry, providing greater flexibility &

protection during system upsets

protection during system upsets

·

reduction / elimination of maintenance

costs & production Losses.

Aquapharm Chemicals Pvt. Ltd, 9th & 10th Floor, Amar

Synergy, 12-B, Sadhu Vaswani Road, Pune 411001, Maharashtra, India

Phone: +91 20 6609 0000

Comments

Post a Comment